How Holleran’s doubled their Productivity and got the Job Done!

10 Dec 2004

(Who said ATWS wasn’t the best thing since sliced bread?)

M. Holleran Ltd., who are a well-known railway contractor, were awarded a contract putting cabling into ducts and installing ballast boarding. The work is part of the Southern Power Supply Upgrade Inner London Project for Network Rail. With third rail electrification between Streatham Common and Selhurst, a distance of some three and a half miles, the work in the down cess of the Brighton lines was never going to be easy!

M. Holleran Ltd., who are a well-known railway contractor, were awarded a contract putting cabling into ducts and installing ballast boarding. The work is part of the Southern Power Supply Upgrade Inner London Project for Network Rail. With third rail electrification between Streatham Common and Selhurst, a distance of some three and a half miles, the work in the down cess of the Brighton lines was never going to be easy!

T2’s lasting half an hour or less!

Work started on November 8th and was programmed to take just four weeks of seven nights a week working. Previously Holleran’s had worked in “Green Zones” using T2 protection at night. But inevitably productivity was low due to darkness and the fact that it could take up to 20 minutes to obtain a T2, which often had to be handed back just half an hour later!

An all too familiar story, which leads many to question whether or not the time has come to update and improve Network Rail’s RIMINI standard which decrees that “green zone working should always be a first choice.”

Productivity at least doubled using ATWS

Holleran’s Assurance Manager had a better idea. He knew that restrictions on the use of Track02, the automatic track warning system (ATWS), which is radio based, needs no cables and can provide individual warning through harnesses, had all been lifted some time ago.

He was able to persuade Joe Holleran that provided the client, SABCO could be persuaded to agree to work “Red Zone”, protection by ATWS could be just as safe. Perhaps even safer when you considered the number of individual T2’s needed and it would be more productive. SABCO agreed and the work has gone well. Holleran’s admit that productivity has improved.

More ATWS to be used on the Power upgrade works

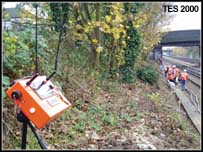

TES2000 provided and operated the ATWS equipment. In areas where the positions of signalling equipment prevented use of Track02, Autoprowa’s lookout warning system was used instead. Sensors cannot be placed within 400 metres of signalling equipment for fear of interference.

Track 02 was worn and liked by around 20 men each shift. Another unconfirmed report indicates that at one stage 27 were wearing harnesses for protection. No surprise then that Track02 is now being considered for use on other sites to improve productivity and safety on the remainder of the Southern Power Supply Upgrade works.

Maybe there is a wider lesson for us all. Don’t disregard new equipment because the safety professionals say it is good for you. It may make the work easier, save you money and be safer as well!!

Protecting 27 with harnesses, a UK record?

Daren Gardener of Holleran’s summed up his feelings by saying “Track02 is a safe piece of equipment. When set up for planned work it can provide a safe system of work with 20 or more men all wearing harnesses, which come with the equipment.” Dave Beecroft of TES2000 Ltd is pleased to have been given the opportunity to show what the equipment can do. Is protection of 27 track workers at once a UK record?

TES2000 also have an ongoing contract to provide protection to Bakerail using Autoprowa for leaf fall survey teams on Network Rail’s Southern Territory at Wanborough and Oxshott. The Autoprowa systems were installed overnight on 28/29/30th September and have been available for use from the start date of the leaf fall season by the survey teams. The season ends on December 3rd.

Many people have been waiting a long time to see a good news story like this. Now that the cost benefits have been so dramatically demonstrated can we expect to find ATWS specified in suitable future contract specifications? Can we afford not to do so?