Innovation has its rewards

01 Sep 2009

Innovation has its rewards

Innovation has its rewards FLI Structures, part of the Haley Steel Group, is a leader in the design, manufacture, supply and installation of screw-piled foundations - a rapid steel foundation solution. Supporting various structures in both tension and compression, FLI screw piles are suitable for many rail structures including signal posts, gantries, cabinets, lighting towers and platforms. The company also specialises in steel structures such as steel grillages and masts.

FLI Structures is providing the 2,000 radio masts and foundations for Network Rail's multi-million pound GSM-R project which will provide a national system of secure train driver-to-signaller communications, helping to deliver safe running and improved performance.

Innovation Award

FLI Structures recently won the Network Rail Partnership Award for Innovation which was presented to Justine Garbutt, FLI's General Manager, by Jerry England, Network Rail's Director of Engineering. This award recognises an organisation that has developed new approaches for mitigating or solving a problem faced by Network Rail.

The traditional method of providing mast foundations has relied on concreted site excavations. This has been superseded by a system of steel grillages, anchored down by screw piles or precast concrete blocks. These new foundation solutions enable sites to be built faster, reducing delays to trains from engineering work.

The Innovation Award was given for the development of a new steelwork foundation for sites with tight access, where the standard grillage could not be used. A trial site was found and FLI designed, manufactured and installed the new grillage which evolved from a concept into reality in just two weeks.

The Innovation Award was given for the development of a new steelwork foundation for sites with tight access, where the standard grillage could not be used. A trial site was found and FLI designed, manufactured and installed the new grillage which evolved from a concept into reality in just two weeks.

The new grillage is lighter and 40% cheaper than the standard and is compact and foldable for easy and safe handling. It can be delivered and installed on sites with restricted access and uses smaller site plant. The expected cost saving to Network Rail is in the region of £1.65 million.

After congratulating all the nominees, Network Rail's Chief Executive Iain Coucher stated: "Our finalists have made a real difference to Network Rail and the millions of people who travel by rail every day...we are a nation of innovators but we still look too much to the past, to outdated methods, tools, processes and ways of doing work. We are reluctant to take risks, to experiment with new materials and technology".

New product development

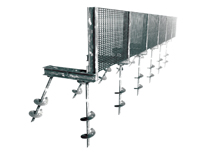

Now FLI Structures has announced the launch of its innovative, patented, screw-piled retaining wall. The FLI Wall has been engineered and designed as an all-steel retaining wall, capable of sustaining tension and compression loads as well as being installed in reduced time. With the use of screw piles, it is the ideal solution for refuges, ballast retention, equipment location, layby/safety areas and cess widening.

The wall comprises a steel ‘L' frame consisting of 2-metre infill panels. The system is fully galvanised with panelling made from steel mesh, precast concrete or railway sleepers. The wall measures up to 2 metres in height with an unlimited length and is secured by screw piles - the number being determined according to the length, ground conditions and loadings.

the number being determined according to the length, ground conditions and loadings.

Rapid deployment is one of the many benefits of the FLI Wall, with no requirement for wet trades or concrete curing time. It has a small foundation footprint - useful in restricted access sites - and can be installed in contaminated land.

FLI has a range of standard products but also produces bespoke designs for customers. It is fully certified to ISO 9001, providing good quality design, manufacture, installation and survey services. All manufacture is carried out by Lloyd's certified welders, employing procedures to BS EN European standards. With an in-house design, engineering, manufacture and sales framework, FLI is able to offer a complete solution.

Taken from the rail engineer magazine.