Shoulders, Walkways And Cesses - The Ruglei System

14 Mar 2005

Losing ballast shoulders due to cess-less embankments and at the ends of under bridge ballast walls is a concern for most, if not all, track engineers. (Especially as the early summer track buckle season approaches).

Losing ballast shoulders due to cess-less embankments and at the ends of under bridge ballast walls is a concern for most, if not all, track engineers. (Especially as the early summer track buckle season approaches).

Over the last seven or eight years, and even before reprivatisation, there have been safety concerns over a lack of cess walkways and inadequate places of safety. Narrow, choked and contaminated ballast shoulders and embankment tops can contribute to the generation of wet beds and other maintenance problems in the most surprising places.

Depending on the severity of the problem, sheet piling, concrete crib walling, gabions and even old timber sleepers held up by steel spikes or old lengths of rail have been (and still are) used to mitigate the problem. More permanent (and expensive) solutions include benching the existing embankment and widening it if enough land is available. Piling, using bored concrete piles with a capping beam walkway is another solution but is both expensive and slow to install.

A Swiss engineered solution installed at 10 metres an hour

Now we can learn from the Swiss. Their engineered solution is economical and is regularly installed at a rate of ten linear metres an hour! SBB, the Swiss Federal Railway, supported the development of the Ruglei System by Ruegger Geotechnical Systems and Gleisag Construction, which is now patented in all industrial countries. Elwood International Ltd is the sole licensee of the system in the UK and Ireland.

Elwood International specialises in designing and providing geotechnical solutions, such as reinforced soil walls, bridge abutments, reinforcement of steep embankments and pre-cast arch bridges. This Swiss system fits well with their area of expertise.

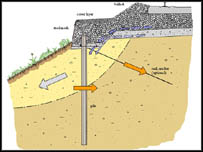

Known as the "Ruglei System" it is made up of galvanised steel facing grids, mesh inserts, hook ties, connectors and piles .The piles are driven steel sections, usually old rails, which have more than enough capacity and are very economical. The entire shoulder is replaced by retained ballast or fines-free stone. This assists drainage and discourages the growth of fines-retaining vegetation. Tiebacks can be provided if ground conditions require them.

But in Switzerland pile foundations have proved sufficient without the use of tiebacks on over eighty percent of sites and Elwood expects that this will also be the case in the UK.

Elwood International provides both the design and special components for each installation, and an experienced site engineer on site for every job. Construction is simple and predictable, and is usually carried out by the main contractor. Elwood’s site engineer helps the construction gang achieve a quality job in the shortest possible time. This service is provided in addition to their construction manual.

Thirty two kilometres already installed in Switzerland

The first installation in Switzerland was completed in 1998, and there are now over 32 km installed on their railway. The rapid installation rate is one reason why the Swiss are so keen on the Ruglei system. Monitoring in 2004, of many of the early structures including that built in 1998 at Bazenheid, showed no deformation over its six years in service and confirmed the SBB’s confidence in the system.

Ruglei strengthened embankments have met the stringent Swiss Rail Authorities standards for embankment differential settlement. The system is now gaining favour in Germany, Italy, Ireland and France as well as here.

Already Metronet have taken advantage of Elwood’s offer of a free feasibility study based on embankment cess section and geotechnical information. Consequently a length of "Ruglei" embankment strengthening is soon to be installed at Dagenham on London Underground’s railway for Metronet.